Here’s a more detailed breakdown:

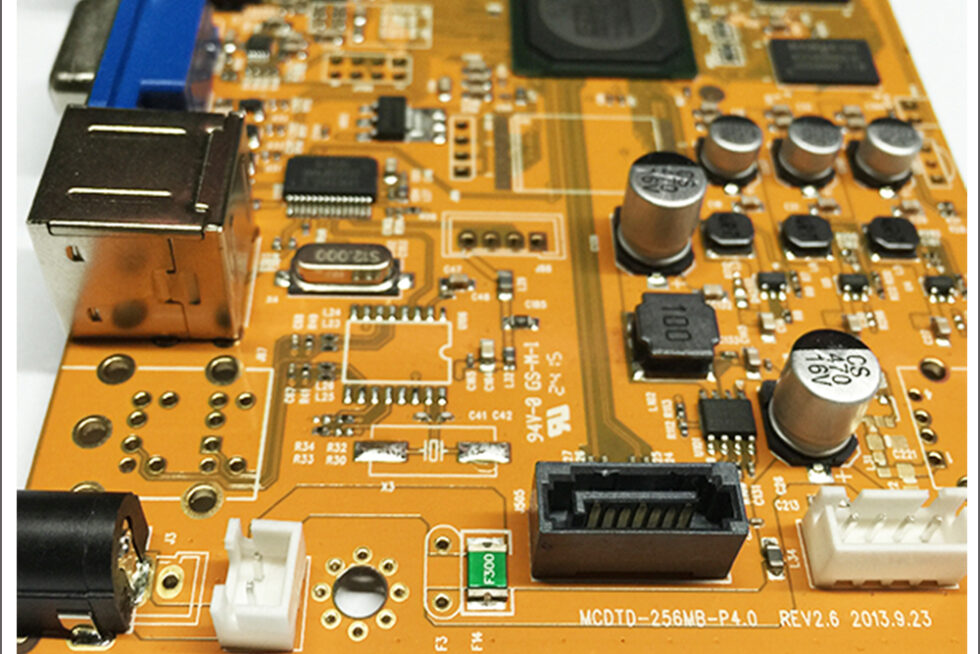

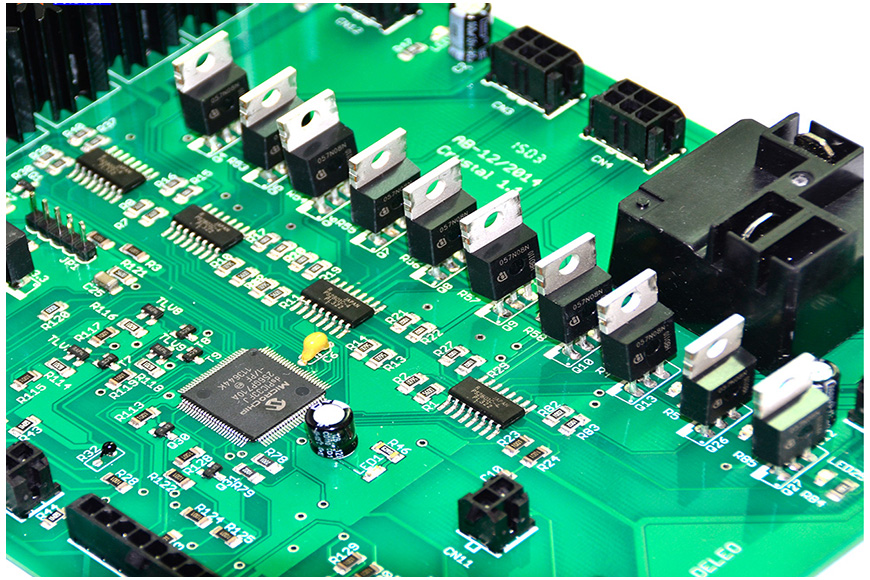

1. The PCB:

A PCB is a non-conductive substrate with conductive pathways etched onto it. These pathways, typically copper, connect the various components on the board. PCBs provide mechanical support for components and enable electrical connections between them.

2. Assembly Process:

Solder Paste Printing:

A stencil is used to apply solder paste to the pads where components will be placed.

SMT Component Placement:

Automated machines precisely place surface mount components onto the solder paste.

Reflow Soldering:

The board is passed through a reflow oven, where the solder paste melts and forms permanent connections.

Through-Hole Component Insertion:

Components with leads that need to be inserted through the board are placed and soldered, often using wave soldering.

Inspection and Testing:

Thorough inspections, including automated optical inspection (AOI), X-ray inspection, and functional tests, are performed to ensure quality and functionality.

3. Key Aspects of PCB Assembly:

DFA (Design for Assembly): Designing the PCB with assembly in mind, ensuring components can be easily placed and soldered.

High Mix Assembly: Handling both SMT and through-hole components on the same board.

BGA (Ball Grid Array) Assembly: A specialized technique for mounting components with solder balls on the underside.

Prototype and Low-Volume Assembly: Emphasizing flexibility and close communication with the customer.

Turnkey Assembly: A service where the assembly house handles all aspects of the process, from component sourcing to testing and packaging.

IPC Standards: Adhering to industry standards like IPC-A-610 for quality assurance.

What is China PCB Assembly process?

china PCB Assembly, PCB Assembly from china shenzhen Golden Weald Electronic Co., Ltd, 27 years old factory.