Advantages Of PCB Assembly In China- Golden Weald Factory

PCB assembly China has many benefits when compared to other alternatives, and we would like to discuss just a few of them here.

• Seasoned professional touch: there is plenty of information online and tons of videos that any individual can utilize to embark on do-it-yourself projects for PCB manufacturing projects. However, most of these will not result in professionally finished work and are simply hobby projects.

In many cases, it is always best to leave the skilled labor to professionals, and this is very true in the manufacture and assembly of PCB’s. Excellent PCB manufacture and assembly companies like golden weald have the full set up laced with error spotting abilities and expert testing of your final PCB. This way you have confidence and can concentrate on creating your final product.

• Hub of technology production: there are many good PCB companies around the world, but China is already known as the location for the significant production of technology. This is probably due to a combination of low labor costs, competent technicians to oversee the process and an advanced system of toxic waste disposal.

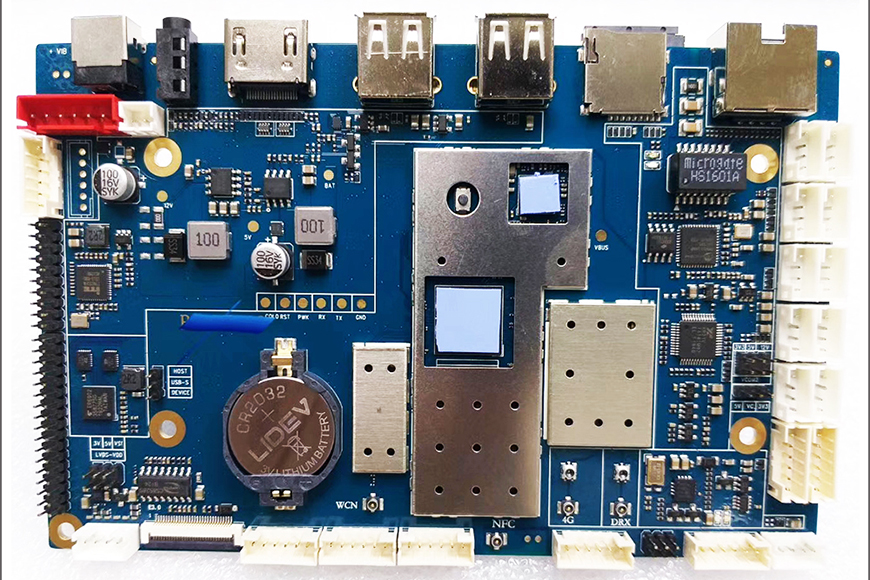

• Small-sized, multifunctional PCB’s: PCB assembly China boards are small in size and only getting smaller by the day. They are also used in a plethora of applications, turning laptops and smartphones into more powerful machines with higher features. These small PCB’s are playing an essential role in constructing more advanced and outstanding devices.

What You Should Know About China PCB assembly Service

Due to continual advancements in modern technology, the size of circuit boards keep shrinking with time, but the smaller sizes don’t hinder circuit boards from being extremely reliable and vastly multifunctional. Dues to this fact, china PCB assembly covers a wide range of elements that indirectly or directly controls the smooth running of PCB boards.

China remains a leading giant in electronics manufacturing worldwide and no doubt because of its sturdy political environment, plenteous natural and human resources, favorable national policies and constantly rising international influence. We seek to educate global customers on the special characteristics that strong PCB China assembly companies have to offer the market.

• Main Components For PCB Assembly: PCB’s might be small, but there are many details to them, especially with the increasing complexities being introduced as technology evolves. When you engage a professional PCB assembly China company like Golden Weald electronic, these are the common leading components of PCB assembly in China:

♦ Design: a PCB design file containing an idea with details of fundamental parameters.

♦ Prototyping: a direct way to test is the idea in the design stage is feasible and becomes a key reference during mass production.

♦ Fabrication: laying a foundation for electronic connection by setting up the core parts of the PCB.

♦ Assembly: sourcing and implementation of components.

♦ Rework and repair: a small section for thorough checks.

♦ Sourcing: connecting manufacturers with customers for parts like copper foil and covering substrate.

• Regular Procedure To Get PCB Assembly From China: engaging the services of Chinese PCB companies like Golden Weald electronic involves certain basic procedures. PCB assembly in China comes with many advantages but still complies with approved trade policies around the globe. The following steps will set you on a clear path to acquiring PCB assembly from China:

♦ Create PCB design from your idea: create a rational PCB design file upon which your dreams will take wings.

♦ Choose a trusted assembly company in China: you can utilize the tips provided below in selecting the perfect PCB company.

♦ Make a prototype order: after sorting the idea and getting the right company, you get the ball rolling at this stage.

♦ Validate the standards and performance of your prototype: inspect, correct, and smooth the prototype.

♦ Make a mass order: once you get an error-free pass, go ahead and place mass order.

♦ Modify the design to fit your mass order: make modifications on the prototype to fit your mass order where necessary.

♦ To confirm the final design so production can start: mass order production commences upon confirmation.

♦ Wait for your order to be delivered and use them on your electronics: pay for the order, choose a delivery method, and wait for fulfillment.